Inside a John Deere 6320SE PowrQuad Transmission Rebuild

This John Deere 6320SE needed a PowrQuad transmission rebuild after thrust washer failure. The mechanic replaced other parts while they were there, saving money and time all round…

Home > Case Studies > Inside a John Deere 6320SE PowrQuad Transmission Rebuild

Even the most reliable machines have their breaking point, and this John Deere 6320SE had done some real hard work.

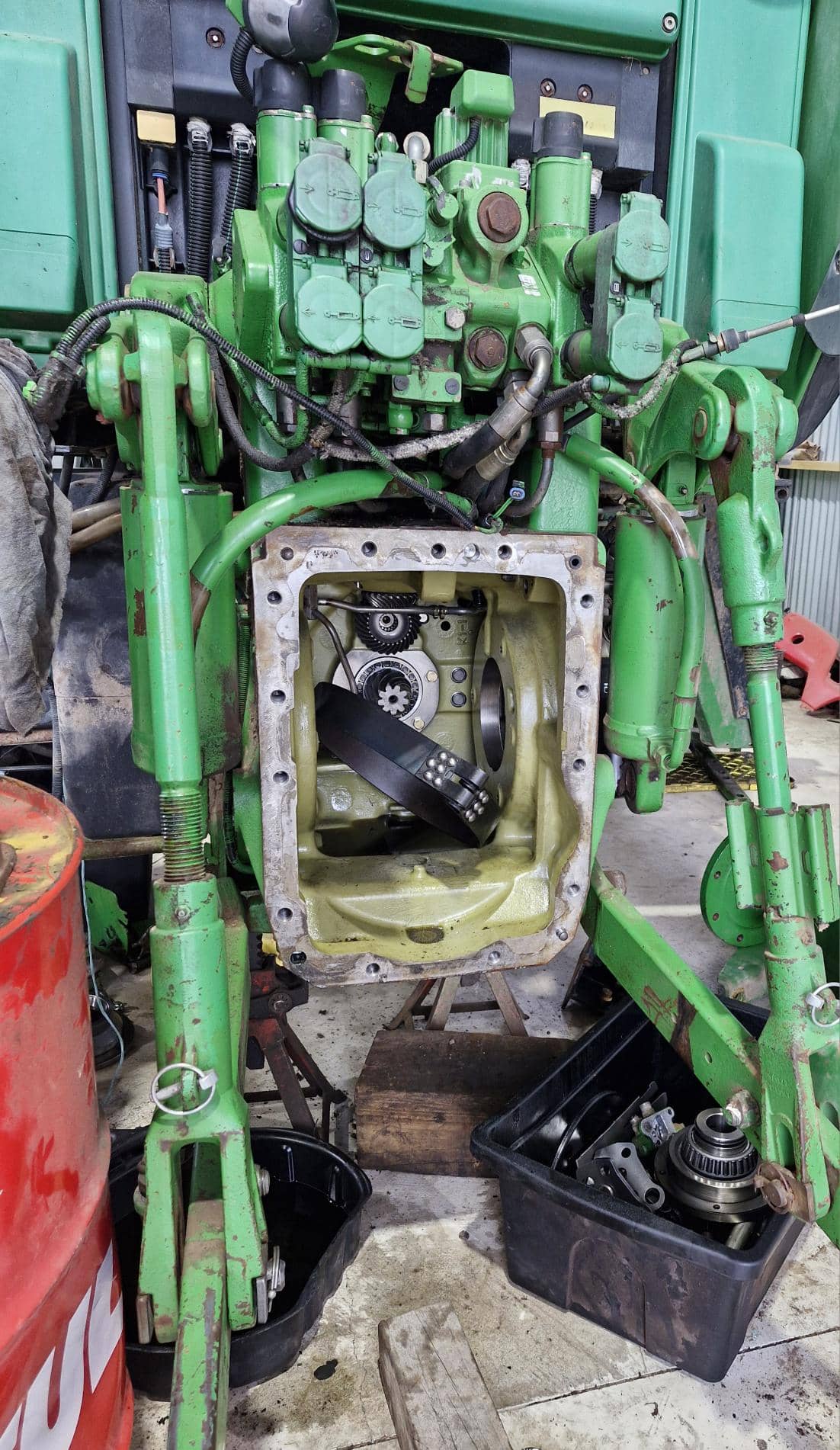

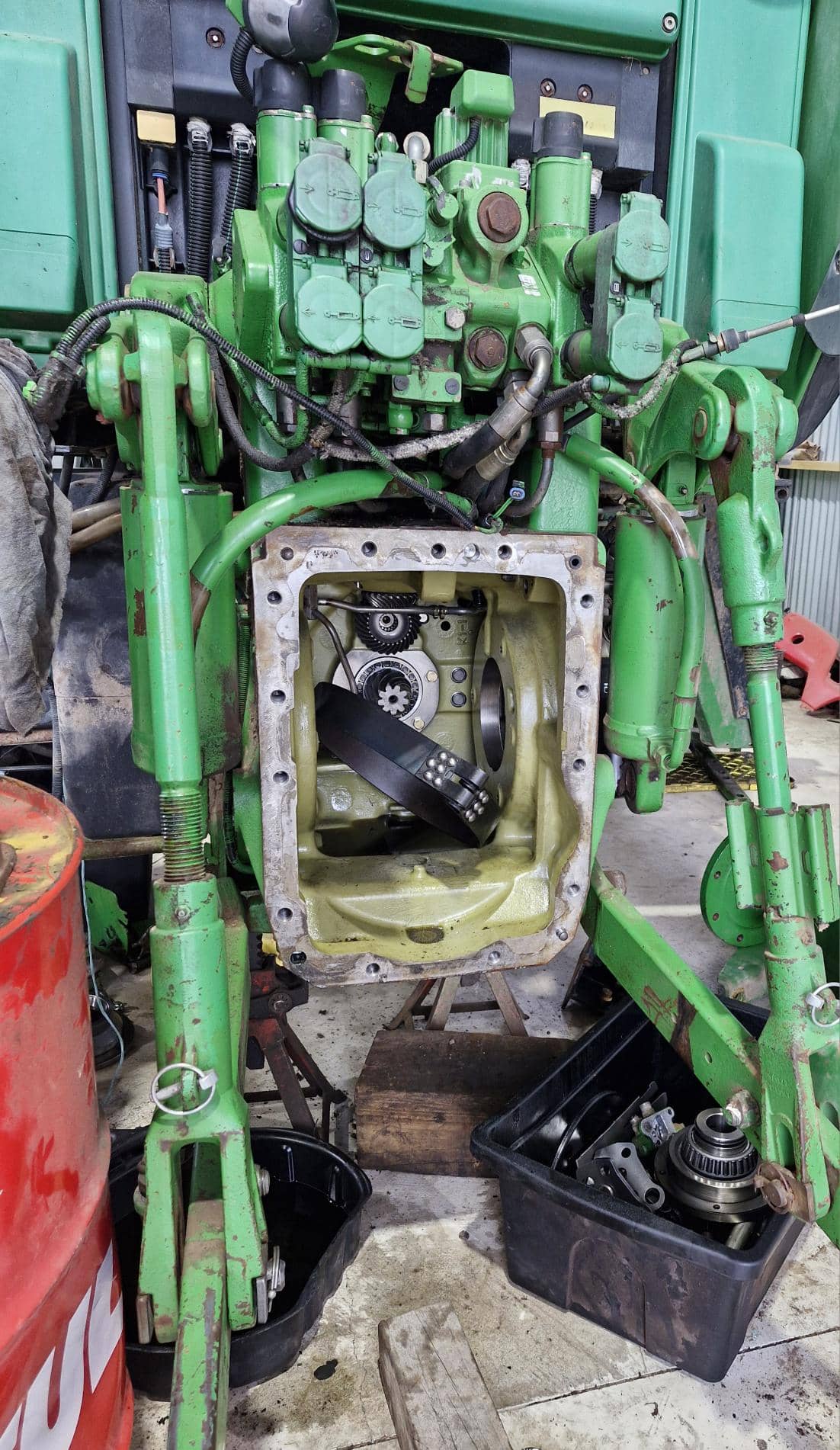

When this tractor rolled into a Hawkes Bay workshop, they found a completely destroyed thrust washer deep inside the PowrQuad transmission. This had caused many issues inside of the transmission and meant a costly replacement of several components was needed.

While the transmission was apart, the mechanic decided to proactively replace additional components to refresh the clutch – not because they were damaged, but because they were accessible and due for attention.

This is smart repair strategy. When you’ve already invested in the labour to dismantle a transmission, replacing wear items that might fail in the next 500-1000 hours makes economic sense. It prevents having to tear the transmission down again soon after.

Here’s where we provided real value: we supplied a mix of OEM and quality aftermarket parts to cut down the massive costs of a genuine rebuild while still delivering the same quality and reliability as genuine parts. By having the option of OEM and aftermarket parts, we were able to save the customer big $$$$ on this job.

We supplied everything needed to get this 6320SE back in the field including:

R101187 – Adapter Second Sun Gear

Central to the planetary gear system, ensuring reliable power transfer.

RE280055 – Clutch Drum

Essential for smooth gear engagement and preventing future shifting issues.

AL174123 – Torsional Damper Plate

Absorbs vibration and shock loads between engine and transmission.

L225515 – Transmission Splined Flange

Critical for proper torque transmission without slippage.

Plus a complete set of gaskets, seals, and bearings.

The frustrating part about these jobs is that there is no warning. Failures in these PowrQuad transmissions are often spontaneous – the tractor operates normally one moment, then suddenly you’re facing a major issue. There’s no maintenance schedule or inspection that can reliably prevent this type of failure without taking the entire transmission apart for an inspection.

For farmers and contractors, this unpredictability is particularly challenging. A machine down means work isn’t getting done and rebuilds are never quick or cheap.

This is why it is recommended to replace other parts in the transmission while you’re in there. When you’ve already invested so many hours tearing down a transmission, replacing other wearing parts within the transmission will save the customer a lot of money and time compared to doing the job twice.

We guarantee to put the right parts in your hands, and aim to make it easy for you in the process.

Trusted by tractors. Parts made easy.

This John Deere 6320SE needed a PowrQuad transmission rebuild after thrust washer failure. The mechanic replaced other parts while they were there, saving money and time all round…

OEM vs aftermarket and genuine tractor parts: what’s the difference? Everyday our parts team hear the question “Is it genuine

As any tractor mechanic can attest, there’s nothing quite as satisfying as bringing an old tractor back to life.

By offering the full gamut of Aftermarket, OEM, Genuine and Used parts, across loads of brands, your ability to find what you need just jumped up a notch.

Parts Disclaimer: Original equipment manufacturer’s names and part numbers used on this website and other documentation are quoted for reference purposes only, and are not intended to suggest that all parts supplied by Propart Ricambi are made by the original manufacturer.

Join the ProPart party and receive tips, updates, and great yarns from our team.

Monday–Friday:

7:00am – 5:00pm (NZ time)

View your local time →

We guarantee a fast response for all enquiries!

"*" indicates required fields

Get in fast before sale allocations are exhausted!